The 9-Minute Rule for Spandrel Glass Film

Table of ContentsSpandrel Glass Explained - QuestionsThe Main Principles Of Spandrel Glass Frit 10 Simple Techniques For Spandrel Glass Explained

The infill wall surface is an external upright opaque sort of closure. Relative to various other classifications of wall surface, the infill wall surface varies from the dividing that offers to separate two interior spaces, yet also non-load bearing, and also from the lots bearing wall surface. The last carries out the same functions of the infill wall surface, hygro-thermically and acoustically, but does fixed functions also.

The safety versus fire is one of the demands that is frequently called for to rooms walls. what is spandrel glazing. As generally the extra traditionally used materials (blocks, blocks and also mortar) are not sustain items, it is reasonably very easy to accomplish the demands associating to the limitation of spread of fire, thermal insulation as well as architectural stamina, which in severe instances, should be guaranteed for 180 mins.

Indicators on What Is Spandrel Glazing You Should Know

This requirement has a direct impact on the building and construction of the wall surfaces. The thermal regulations are demanding progressively higher worths of thermal resistance to the walls. To meet these needs brand-new items and building systems, which make sure that the thermal resistances requested by the regulations will certainly be supplied, are developed.

In general, in one of the most regular instance of border get in touch with in between the masonry panels as well as the light beams and also columns of the RC framework, the infill panels interact with the framework, despite the lateral resistance ability of the structure, and imitate structural components, overtaking lateral loads up until they are terribly damaged or destroyed.

The main issues in the regional communication between frame as well as infill are the development of brief light beam, brief column effect in the architectural aspects. The zones in which additional shear forces can occur, acting locally on the extremities of the light beams as well as columns, must be dimensioned and transversally enhanced in order to surpass safely these pressures.

All About Spandrel Glass Frit

A wall being composed of two parallel single-leaf walls, effectively linked with each other with wall ties or bed joint reinforcement. The space between the leaves is left as a continuous tooth cavity or filled or partially loaded with non-loadbearing thermal insulating material (spandrel glass frit). A wall surface consisting of 2 leaves divided by a dental caries, where one of the leaves is not adding to the toughness or tightness of the other (possibly loadbearing) leaf, is to be pertained to as a veneer wall.

[edit] Introduction are a type of cladding built in between the structural members of a building. The architectural framework provides assistance for the cladding system, and the cladding gives separation of the inner and outside settings. Infill walling is different to various other types of cladding panel in that it is fixed in between framing members rather than being affixed to the exterior of the frame. It has diamond-shaped openings over its surface, providing it a distinct look. These panels supply superior stamina for a building exterior or other application. For architectural security as well as an enhancement to the design of your building, staircase, pathway or various other location, pick these infills.

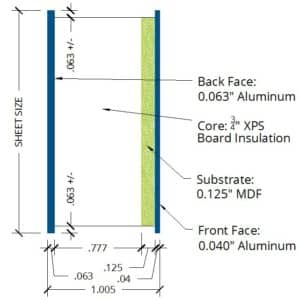

Holes in the shape you require are punched into metal sheets to give a strong material that stays long lasting. You can get rounded, square, slotted and various other holes in several different patterns that benefit the layout you want. Infill panels are used between blog posts of guard barrier to develop the barrier for loss defense on stairs, balconies, and walkways. Perforated infill panels, woven cord panels, or laser cut panels provide fascinating ways to fill the space between blog posts. Infill panels are typically installed on building exteriors as a curtain wall, a rainscreen, or assistance for various other cladding material. Metal infill panels give an excellent means to include safety to locations that require that. They are reasonably lightweight as well as can be included or removed as desired. They let light and also air with as well as can be created with imagination to enhance the room and also the appearance of the building. They enable for airflow as well as provides safety from within, all while screening the sight from the exterior as well as providing an unique and also fascinating style for the structure. There are many methods to cover a ceiling to hide the joists or trusses as well as energies that run in ceilings. One method is with using steel infill panels, especially when an extra commercial look is preferred. Infill panels are a terrific method to load in the areas of the support structure for covers and also sunshades. They supply shade, design, and also permanency. Bus sanctuaries, Park and also Trip waiting locations, Band shells, Parks, Zoos, Playgrounds, Residential housing are all locations where infill panels are made use of. Aluminium insulated infill panels are created with a protecting core sandwiched between 2 thin aluminium sheets. Infill panels usually used for home windows, doors and also curtain wall surface applications, give high performance insulation for the building and provide an eye-catching modern-day appearance. Participating infills form a composite architectural system with the bounding structure, enhancing the strength as well as rigidity of the wall system and its resistance to quake as well as wind lots. Non-participating infills are outlined with architectural voids between the infill and the boundingframe to stop the unexpected transfer of in-plane tons from the you can try these out structure into the infill. Building and construction of concrete masonry infilled frameworks is fairly simple. Initially, the bounding framework is created of either strengthened concrete or architectural steel, then the masonry infill is built in the portal space. This building and construction sequence allows the roof or floor to be built prior to the masonry being laid, permitting rapid construction of subsequent stories or application of roof product. The system acts as a monolithic cantilever wall where small stress and anxiety focus take place at the four corners, while the middle of the panel develops an approximately pure shear stress state. As loading continues, separation takes place at the user interface of the masonry and also the structure members at the off-diagonal edges. Getting involved stonework infills resist out-of-plane loads by a curving device. As out-of-plane lots raise past the flexible limit, flexural splitting occurs in the stonework panel. This fracturing(comparable to that which takes place in reinforced stonework )permits curving activity to withstand the used loads, supplied the infill is built tight to the bounding frame as well as the infill is not as well slender. If a void exists between the infill and the framework, the infill is considered taking part if the void is less than in.(9. 5 mm) as well as the calculated displacements, according to MSJC Code Area B3. 1.2. 1. Nonetheless, the infill can still be developed as a participating infill, gave the computed toughness and also rigidity are minimized by fifty percent

. The maximum thickness allowed is one-eighth of the infill elevation. The MSJC Code requires getting involved infills to fully infill the bounding framework and also have no openingspartial infills or infills with openings may not be thought about as part of the side pressure standing up to system because frameworks with partial infills have normally not carried out well during seismic occasions. The in-plane layout is based on a braced frame design, with the stonework infill working as an equal strut. The width of the strut is established from Formula 1(see Number 1). The term strut, developed by Stafford Smith and Carter(ref. 2 )in the late 60s, is the particular tightness parameter for the infill as well as provides a step of the relative tightness of the frame and the

infill. The angled strut is created within the panel as an outcome of angled tensile cracking. Flexural cracking failure is rare due to the fact that separation at the masonry-frame mozzi infill panel interface typically takes place first; after that, the lateral pressure is resisted by the angled strut. As gone over above, the nominal shear ability is figured out as the least of: the capacity infill corner crushing; the horizontal part of the go to my site pressure in the equivalent strut at a racking variation of 1 in. 2.4, determined along a bed joint. The displacement limitation was located to be a far better forecaster of infill performance than a drift limit. Usually, the infill stamina is reached at lower displacements for tight bounding columns, while more adaptable columns result in the toughness being managed at the 1-in.(25-mm)displacement limitation. 2 is for unreinforced stonework, use formulas from that area does not always suggest that the infill product need to be unreinforced. The equations made use of in MSJC Code Section 3. 2 are a lot more plainly pertaining to failure along a bed joint as well as are consequently much more suitable than formulas from MSJC Code Area 3. The formulas utilized in the code are the outcome of contrasting various logical techniques to speculativeresults. They are toughness based. The speculative results utilized for comparison were a blend of steel and also strengthened concrete bounding frames with clay and concrete masonry. While some techniques presented by numerous researchers are fairly complicated, the code formulas are fairly straightforward. As out-of-plane pressures are related to the surface of the

infill, a two-way arch creates, supplied that the infill is constructed tight to the bounding structure. The code formula models this two-way curving activity. As previously discussed, the maximum density enabled calculation for the out-of-plane capacity is one-eighth of the infill height. Bounding structure members that have different cross sectional homes are made up by averaging their residential or commercial properties for usage in

the code formulas. NON-PARTICIPATING INFILLS Due to the fact that non-participating infills support only out-of-plane tons, they must be outlined to avoid in-plane load transfer right into the infill. Therefore, MSJC Code Area B. 2. Connectors are not allowed to transmit in-plane lots. The masonry infill may be designed to span up and down, horizontally, or both.